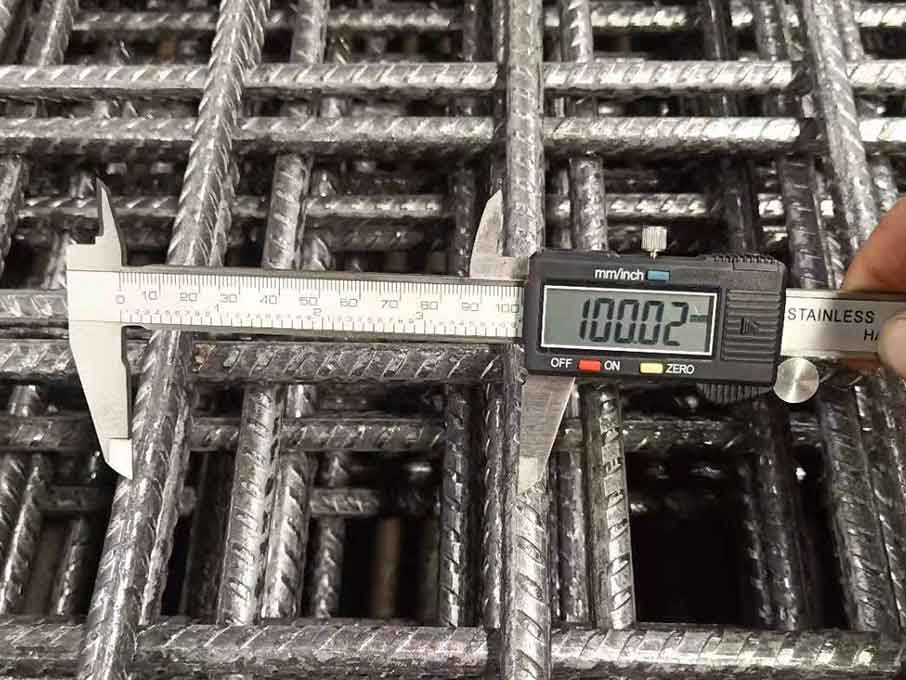

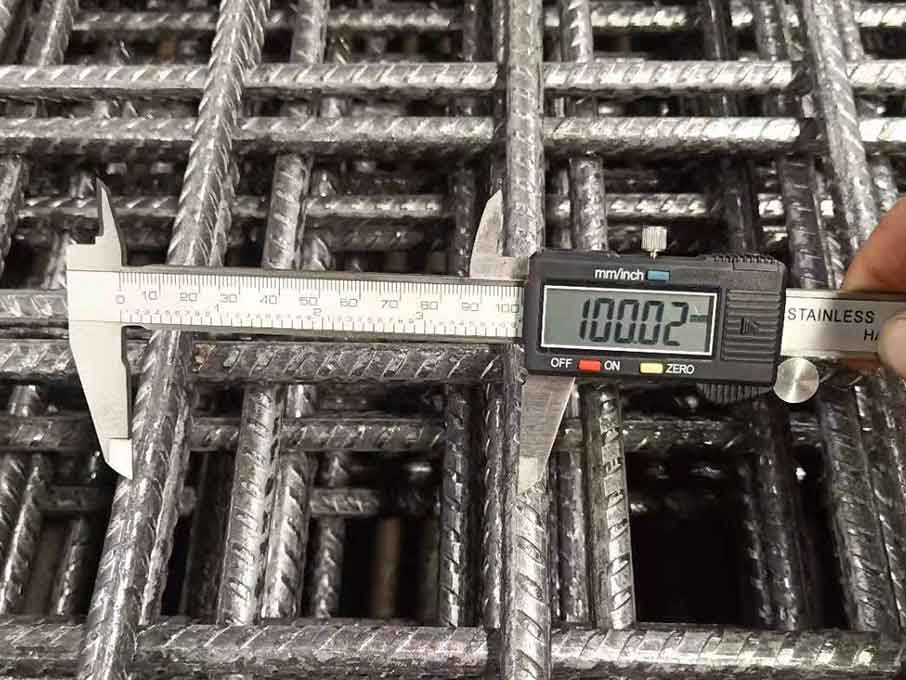

Reinforcement Mesh is also called reinforced welded mesh, welded mesh,

building mesh, welded mesh, reinforced mesh, etc. Reinforcement mesh is a mesh

made by longitudinal and horizontal reinforcing steel crosses through binding or

welding. Reinforcement mesh can be divided into: shaped reinforcement mesh and

formulated reinforcement mesh. Rebar material: CRB550 grade cold-rolled ribbed

steel bar; (threaded steel mesh). Reinforced mesh is widely used in the

construction of beams and columns, roofs, walls, pavements, bridge decks,

highway cracks, airport runways, tunnel linings, box culverts, dock floors,

factories, etc. engineering.

Reinforcing Mesh With Ribbed

The building reinforcement mesh is firstly made of high-quality low-carbon

steel wire, stainless steel wire with Reinforcing Mesh With Ribbed or

cold-rolled round steel bar at right angles in the longitudinal and transverse

directions, and all cross-welded at a certain distance. Construction steel mesh

is divided into hot-dip galvanized, electro-galvanized, PVC coated, dip plastic,

special welding mesh, mainly used in bridges, highways, tunnel backing panels,

high-rise floors, subway culverts, power plant projects, dam foundations,

Various reinforced concrete structural projects such as ports, docks, river

walls, airport runways, etc.

Advantages of reinforced mesh:

1) Significantly improve the quality of reinforcement engineering

2) Significantly increase construction speed

3) Enhance the crack resistance of concrete

4) Has better comprehensive economic benefits

5) Save labor

6) reduce engineering costs

The welded mesh of the building reinforcement mesh should be made of CRB550

grade cold-rolled ribbed steel bar, or CRB510 grade cold-drawn smooth steel bar.

A piece of welded mesh should be welded with the same type of reinforcement.

Welded meshes are divided into two types: shaped and customized. The spacing and

diameter of the reinforcing bars in the two directions of the shaped welded mesh

can be different, but the reinforcing bars in the same direction should have the

same diameter, spacing and length, which have been specified in relevant

standards and regulations.

The Concrete Reinforcing Mesh Manufacturer will briefly answer a few

questions below.

Q: Do roads need to be reinforced?

A: The upper part is compressed and the lower part is tensioned. The

bending strength must be improved, and the concrete pavement must be flexed.

Q: What is anti-cracking reinforcement mesh?

A: The anti-cracking reinforced mesh is a reinforced mesh composed of

reinforcing steel with a spacing of 150-200mm and a diameter of 4-6mm. It

resists the constrained stress caused by the shrinkage and temperature changes

of the concrete in the cast-in-situ slab, and it is an underground waterproof

front-facing protective layer Reinforced meshes that are thicker than 50mm and

the protective layer is too thick to cause the shrinkage of the concrete are

called crack-resistant reinforced meshes. Use parts such as: where no

reinforcement is provided on the floor and roof slab, or where the reinforcement

is insufficient, especially the upper part of the large-span bidirectional slab,

arrange the reinforcement along two orthogonal directions to help reduce the

temperature-induced cracks called temperature bars. The anti-crack reinforced

mesh for underground waterproof head-on protective layer is more than 50mm thick

and required by specifications.